For CANADEL, which was previously distributed in disposable containers, we have adopted refills, a change that cuts plastic roughly 70%.* Compared to replacing the container each time, this reduces the

CO_{2} emissions 0.23 kilograms per unit, which helps protect the global environment.

*Comparison calculated based on plastic usage in existing products (body, cap, inner lid, and spatula) and refill containers

For “DUO The Cleansing Balm,” we have improved the container to be more airtight so that we can ensure product safety even if we do not have an inner lid. By eliminating the inner lid, we have reduced plastic usage and waste.

Note: Excluding Duo The Cleansing Balm Hot a

We are participating in the “LOFT GREEN PROJECT Recycling Program” implemented by THE LOFT CO., LTD. We are implementing an initiative to collect used containers of eligible products in collection boxes installed in LOFT stores nationwide and recycle them as new materials.

- 拡大

- Image of LOFT container collection box

FSC® certification is a system whereby products are sold bearing the FSC label if they were made with wood from forests recognized as well managed or low risk for other factors. We use FSC®-certified paper for all our brands that require paper packaging and for shipping boxes.

Note: Excluding facial products and certain limited edition products

For the presentation boxes of some products, we use GP-certified factories that meet environmental standards for paper, ink, printing, binding, and surface treatment processes. As a procurement company, we are working to achieve the SDGs through our supply chain.

We actively use materials that are printed by the waterless lithography method, a printing technique that does not discharge harmful waste liquids. This helps reduce our use and emission of hazardous substances.

In response to the Consumer Affairs Agency's recommendation of “Logistics Issues in 2024 and Revision of Free Shipping Display,” we have revised the display of “Free Shipping” mainly on our official online store and switched to “Shipping Charges borne by us” from December 2024. We continue to work to improve customer understanding of logistics and shipping costs and promote the realization of sustainable logistics.

Most mail-order/e-commerce items are delivered using compact packaging or mail service. Compact packaging eliminates extra packaging materials, providing the advantage of transporting larger quantities at one time. Since the mail service is delivered to the customer’s home post, they can receive the package even when they are not home, and there is no need for redelivery. These efforts contribute to reducing CO_{2} emissions during delivery.

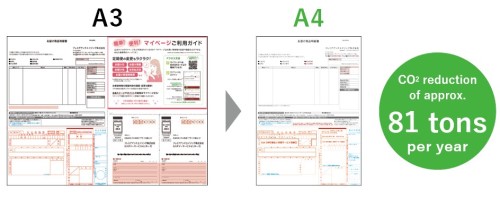

We have reduced the size of the delivery slip included with mail-order/e-commerce deliveries from A3 to A4. This eliminates approximately 81 tons of CO_{2} emissions per year, while also curbing printing costs.

We are working to reduce food waste by effectively using underutilized raw materials as ingredients, while also choosing ingredients that help protect the environment and support local communities. For DUO MEN, we use oil extracted from Japanese pampas grass, an underutilized resource, as a key ingredient.

We do not use microplastic beads, which are thought to harm marine life and, through the food chain, the human body. We will continue to develop environmentally friendly products.

Headquarters uses electricity derived from renewable energy sources provided by the building it occupies and is promoting the creation of an office that also takes energy efficiency into consideration, such as by installing LED lighting and air conditioners equipped with high-performance filters.

At the head office, we are working to reduce CO2 emissions by cutting down on unnecessary usage while maintaining a comfortable office environment for employees, such as by limiting the areas where air conditioning is used based on employees’ working hours.

We have installed monitors in all meeting spaces for both visitors and internal use to discourage the distribution of paper materials. As a result, paper usage has been reduced by approximately 35% compared to before the relocation in November 2023. We are also promoting paperless operations by implementing cloud-based processes such as approval process, expense settlement, and attendance management.